Product properties

1. Excellent flame retardant performance and thermal conductivity;

2. Good electrical insulation properties and mechanical properties;

3. Excellent adhesion, anti-corrosion, anti-ultraviolet and other properties;

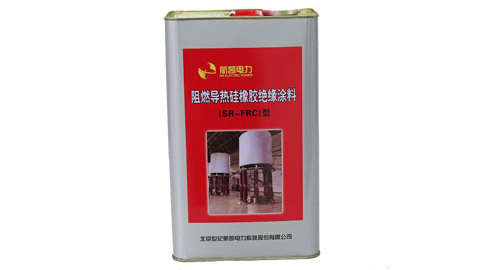

Product pictures

|

|

Front | Back |

Application areas

The application of antiflaming thermal conductivity silicone insulation coating on busbars, wall bushings, high-power motors, dry-type transformers, switch cabinets, cable heads, lead pipes, interlayer structures, capacitors, reactors and other equipment in power transmission and distribution systems can effectively solve the occurrence of bird damage accident of AC filter, eliminate the aging and cracking of heat shrinkable sleeves, poor thermal conductivity, and connection box tripping, etc. to improve the reliability of equipment operation.

|

|

|

|

Reactors | Filters | Reactors | Filters |

Application way

1、Spray & Brush

|

|

|

|

2、Dip coating

|

|

|

|

Technical data sheet

No. | Test Items | Technical Requirements | Measured Values |

1 | Skin-over time,min | ≤45min | 22 |

2 | Contact angle | 114° | 118° |

3 | Hydrophobicity | HC1~HC2 | HC1 |

4 | Hydrophobicity migration | HC2~HC3 | HC1 |

5 | Hydrophobic weakening properties | HC3~HC4 | HC2 |

6 | Hydrophobic Restoration Properties | HC2~HC3 | HC2 |

7 | Flammability | >FV-I | FV-0 |

8 | Volume resistivity,Ω·m | >1.0*1012 | 7.73*1014 |

9 | Power frequency 1min withstand voltage test,kV/mm | >18.0 | 22.1 |

10 | Moisture content | —— | 0.004 |

11 | Thermal conductivity,W/m.k | —— | 1.25 |

12 | Tear strength, kN/m | >7.0 | 17.0 |

13 | Mechanical tear strength,MPa | >3.0 | 4.72 |

14 | Shear strength,Mpa | >3.0 | 3.5 |

15 | Elongation at break | >200 | 350 |

16 | Temperature resistance denaturation (+80℃~-40℃, 24h*10 cycles) | No pulverization, cracking and peeling on the surface of the coating,the adhesion is grade 2 | No pulverization, cracking and peeling on the surface of the coating,the adhesion is grade 2 |

17 | 5000h artificial accelerated aging test | Coating does not crack, pulverize, peel off and fall off | Coating does not crack, pulverize, peel off and fall off |

Temperature Rise Test Report; Type Test Report; Aging Resistance Test report